On August 25, 2023, Fire & Rescue NSW P280A was responded to a HAZMAT incident at a local pet food factory. On arrival, it was discovered that a vat of acid 4 stories above ground level was leaking and spilling onto an electrical panel for machinery, causing a small fire that was extinguished by staff onsite.

We spoke with the crew of P284 about the incident to find out more about it.

The spill was phosphoric acid, which is used in small concentrations in pet food. The spill was on the top floor of the factory, coming from a 1000-liter vat, which provided challenges in rendering the area safe. The acid made every surface it touched extremely slippery, which made the environment more hazardous

Firefighters deployed soda ash to raise pH; however, it was soon realised that there wasn’t enough on the scene. Although more supplies were brought in from Station 280 Dubbo’s store, they were still insufficient. Further supplies were delivered from the local water treatment plant and Station 216 Bathurst, which arrived on Day 2 with their hazmat van. Throughout the course of the two days, crews used close to 400kg of soda ash. The large amounts of soda ash had to be brought to the top floor in buckets so that workers could work their way down from the source of the spill, and crews rapidly learned how difficult it was to move it by hand.

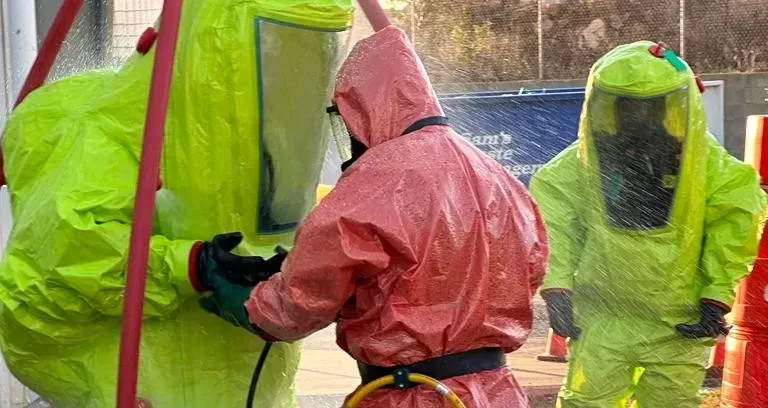

Initially, firefighters were protected adequately by splash suits, but the PPE level was updated to Fully Encapsulated (F.E) suits due to the acid’s extremely low pH in order to prevent any damage to breathing apparatus. The first arriving team established the hot, warm, and cold zones, with the hot zone being the building and the warm zone being a part of the concrete outside, while they awaited the arrival of further appliances. One way in and one way out was the design concept, with distinct entrances and exits.

As firefighters were prepared to make the area safe, the acid leak had stopped, so the leftover acid remained in the vat. Spreading soda ash over all surfaces, crews started at the leak’s source on the top floor and worked their way down. As they travelled, multiple pH readings were collected on each floor to track the progress. Likewise, drainage locations were found, and environmental monitoring was conducted outside. It was found that there were onsite stormwater holding tanks in case there was a chemical spill. The whole incident’s runoff was able to be contained in these tanks.

The Scientific Officer for Fire and Rescue NSW was frequently in contact and offered guidance throughout the entire incident. In order to have a better understanding of the situation, crews captured videos from inside the structure. Also, factory employees were on-site for the duration of the event to address any queries we had about the structure or equipment. In addition, the crew employed the RPAS (drone) from Tanker 300 Gilgandra to survey the entire area where the incident occurred and look for any damaged vents on the building’s roof. For the duration of the incident, NSW Ambulance was stationed on the scene to ensure the safety of the firefighters. The crew of Rehab Vehicle 312 Gulgong provided crew rehabilitation.

Firefighter fatigue was a major issue due to the high temperatures on both days of the incident. Every 20 to 30 minutes, crews were cycled out and given extensive rest periods before being taken back in.

| Pumper 280 Alpha (Dubbo) | Rehab Van 312 (Gulgong) |

| Pumper 280 Bravo (Dubbo) | Hazmat 216 (Bathurst) |

| Hazmat 280 (Dubbo) | Duty Commander Western Slopes 1 |

| CAFS Pumper 284 (Delroy) | Duty Commander Western Slopes 2 |

| Tanker 284 (Delroy) | Senior Instructor Western Slopes |

| Tanker 300 (Gilgandra) – With RPAS (drone) | ESA Outreach Campus Operations Officer (Wellington Training Centre) |

Thanks to FRNSW Station 284 for the information and media!